Zehnder ComfoAir Bearing Damage Repair

It's just after Christmas. The days are quiet and relaxed. But an unpleasant noise comes out of the boiler room? After listening more closely, the culprit was quickly found. It came from our ventilation system. A Zehnder ComfoAir Q350. And obviously it is a bearing damage to one of the fans. The device emits a humming, whistling sound.

In itself is a great device. I'm really happy with it. But within 4 years, this is already the second bearing damage. After about 2 years, just before the warranty expired, we already had the same problem. At that time, the entire fan module was replaced. I can only hope that these modules are repaired and not just thrown away.

In any case, it is to be expected that we would have to bear the costs of a repair, which will certainly not be cheap. On the Internet you can read from 400-500 euros incl. assembly. The pure spare part is about 150-200 euros.

But if it's just the warehouses, the problem should be easy to solve. So I dismantled the system and removed both fan motors. As already described by others on the Internet, standard ball bearings are actually installed. So I went to a specialist dealer for rolling bearings and bought new ball bearings. More precisely four times SKF 608 ZZ (two per engine). Cost a total of about 14 euros.

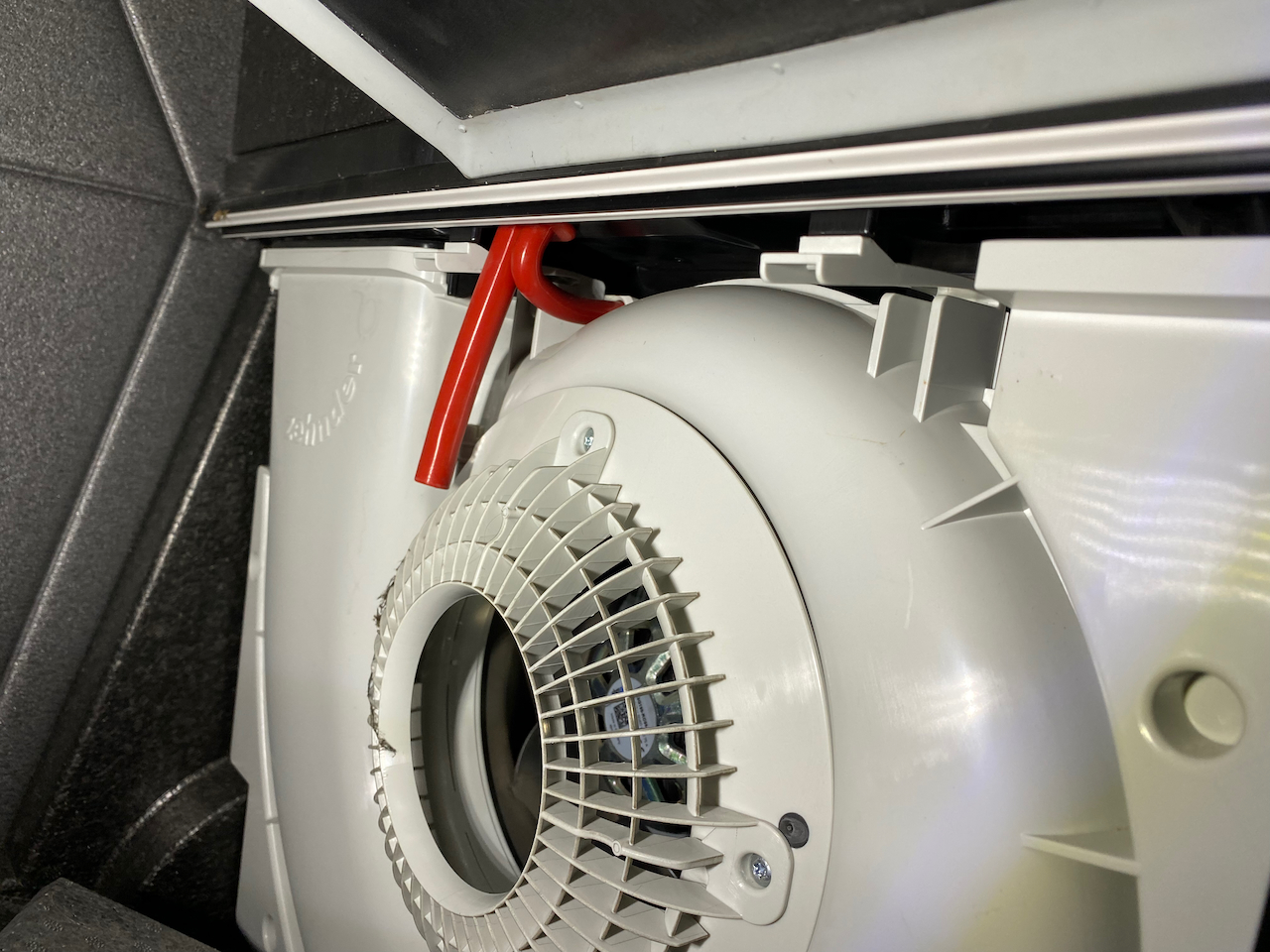

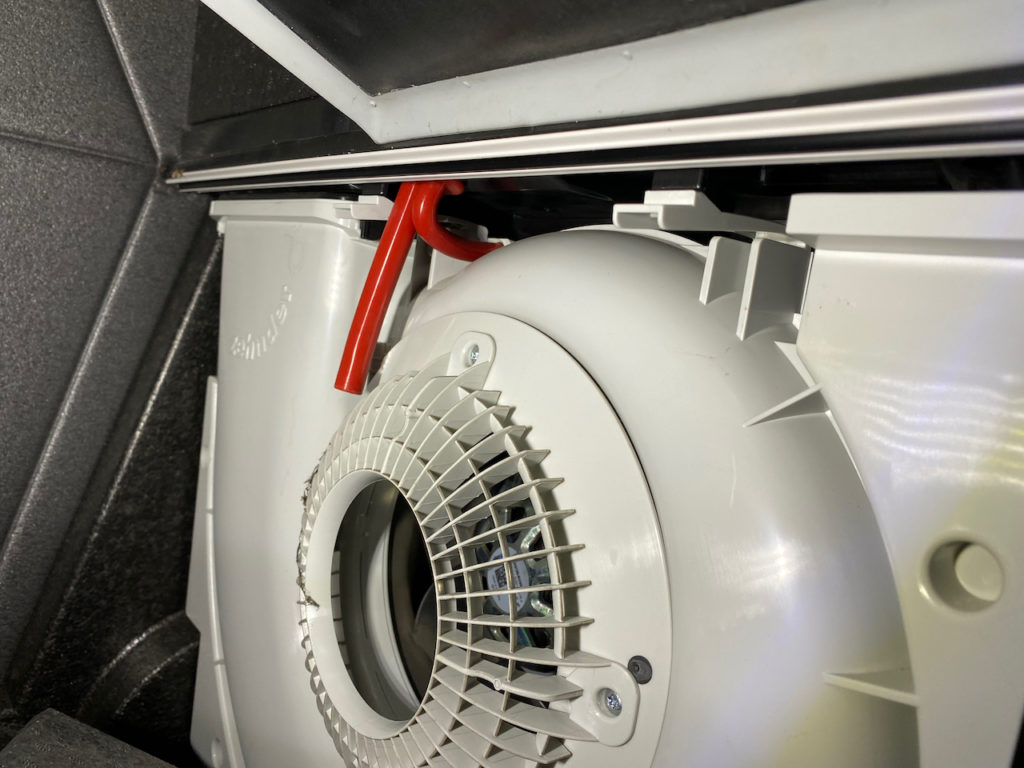

After the front cover and heat exchanger are removed, the fan modules can be removed. To do this, simply press down the two plastic nipples and pull the module to the top of the middle. Before that, of course, loosen the red hoses

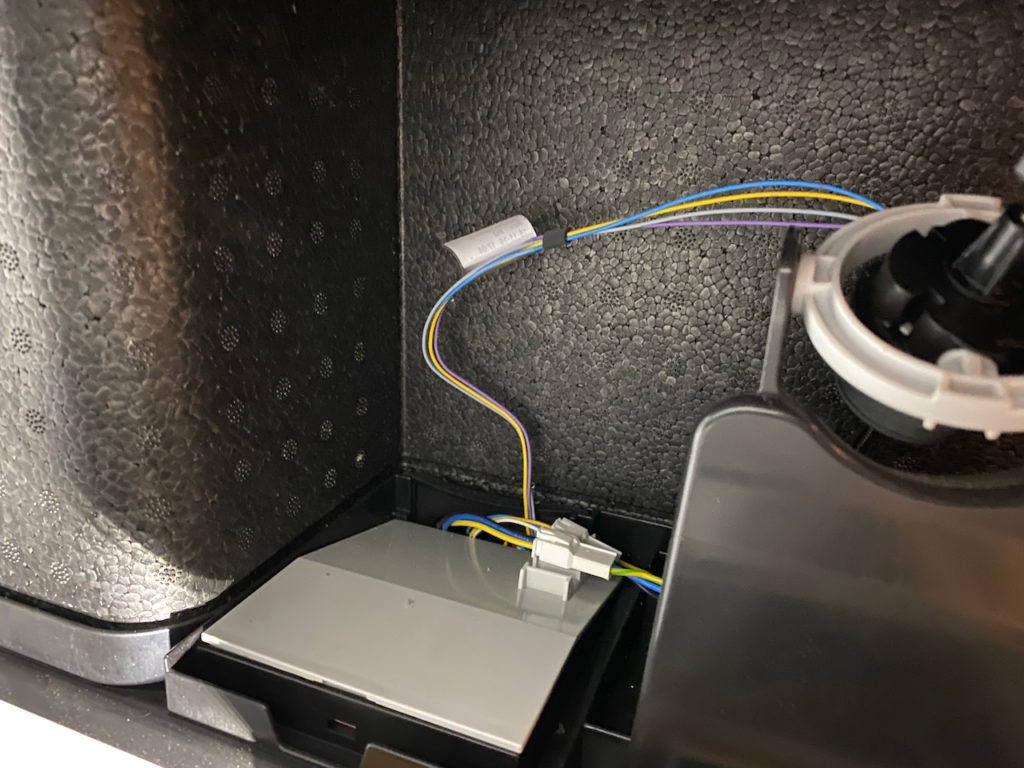

Before the fan module can be removed, the cables must still be loosened. To do this, the flaps for the bypass must be posted. Then a polystyrene cover is removed, under which the connectors are located. These can be easily detached and the cable threaded out.

To disassemble the engine, the 4 screws on the back must first be removed. Then you can carefully and straighten the lid with the cables and the board in it. The connection between electronics in the lid and the windings of the motor is made via pins that are plugged into spring terminals. These should not be bent during disassembly. You can pull a bit. Nothing breaks so quickly.

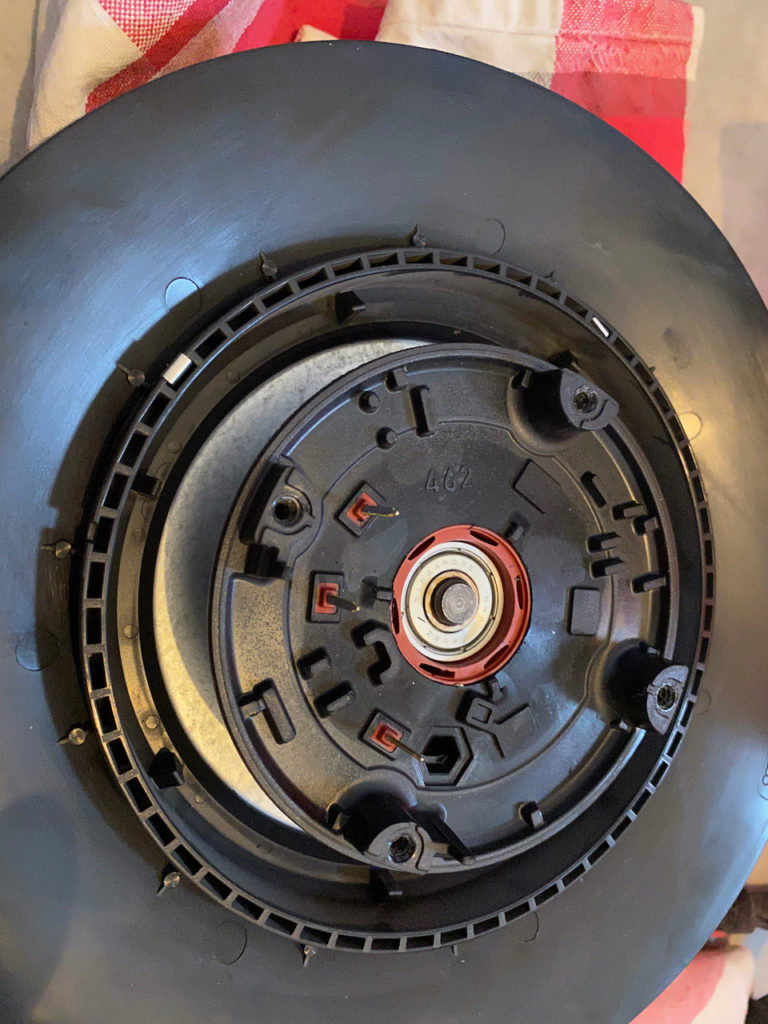

Then you can see the black motor carrier. In the middle there is a cap on the ball bearing, which can be easily removed with a screwdriver.

On the shaft below there is a blasting ring, which can be bent and removed with pliers. When this is done, the inner part with the ball bearings can be pulled from the shaft. If this is not easy, you can carefully hit the inner part from the back with a thin rod through the openings.

The bearings themselves sit in a plastic bushing and are very easy to remove by inserting a thin rod through the upper bearing and tilting it on the bottom one. A gentle hammer blow drops the lower bearing out.

The new bearings are now simply reinserted, everything is cleaned and assembled as it was disassembled. When everything is reassembled, the ventilation system should perform its service again without complaint. I'm curious to see if the new SKF bearings will last longer. If not, I will probably have to change the bearings again in 2 years.

Comments